Handheld Laser Welding

1000W/1500W/2000W/3000W

Easy to Learn & Operate • Simple & Fast to Set Up • Consistent High-Quality Results

EUEN-WELD Unbeatable Benefits

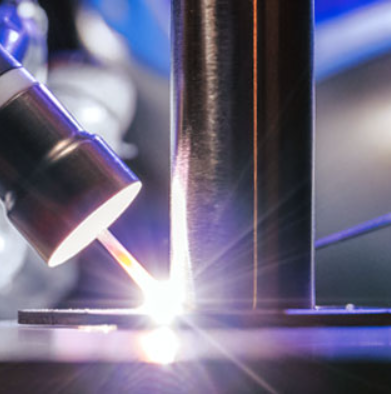

Lasers provide a fast, contactless solution for metal welding, revolutionizing advanced manufacturing across various industries.

With EUEN technology, laser welding has become a dependable, easily automated process that delivers exceptional part quality at the lowest operational costs and requires minimal maintenance.

Key benefits include:

- Precision: Perfect for joining intricate, small components.

- Minimal heat input: Reduces material distortion.

- Non-contact operation: Maintains surface integrity.

- Electrical isolation: No current flows through the welded part.

- Versatility: Welds dissimilar metals, such as copper and aluminum.

- Low maintenance: Ensures maximum uptime.

- Automation-ready: Boosts manufacturing efficiency and output.

Achieve unmatched productivity with high-speed laser welding—offering high-quality results and the lowest cost-per-part.

Enhance your welding precision today → Reach out on WHATSAPP!

EUEN-WELD Turnkey Handheld Laser Welding & Cleaning Systems

- Adjustable Power: Laser welding power adjustable up to 1500 W, ensuring flexibility for various applications.

- Optimized Modes: Preset and user-defined settings tailored for different material thickness combinations.

- Wobble Welding: Advanced controls offering up to 5 mm additional weld width for enhanced precision.

- User-Friendly Design: Rear panel equipped with intuitive connections for power, process gas, and external accessory controls.

- Superior Cleaning Power: Peak cleaning power of up to 2500 W for improved welding quality and seamless finishing.

EXPERIENCE EUEN-WELD YOURSELF!

- Quick and Simple Setup

- Built-In Presets

- Versatile Welding

- Cleaning Capabilities

- Live Q&A

Less Heat & Distortion for More Productivity & Flexibility

Why are more manufacturers switching to welding with fiber lasers from traditional welding techniques?

Staying competitive today demands cost reductions, efficiency gains, and consistent part quality that traditional techniques—dependent on increasingly scarce, highly skilled craftsmen—cannot provide. Thanks to the no-maintenance, high-reliability, and low-cost features of EUEN fiber laser cutting machines, laser welding has emerged as the preferred solution for the manufacturing industry.

Gas Metal Arc Welding (GMAW) vs Fiber Laser Welding

GMAW (Gas Metal Arc Welding), commonly known as MIG welding, uses a consumable electrode and is ideal for larger, poorly fitting parts. However, fiber laser welding offers several advantages over this traditional technique. It eliminates the need for consumable electrodes, requires less edge preparation, and can be easily automated, making it up to 5 times faster. Additionally, fiber laser welding provides superior precision and lower heat input, resulting in improved weld quality and less distortion.

Gas Tungsten Arc Welding (GTAW) vs Fiber Laser Welding

GTAW (Gas Tungsten Arc Welding), or TIG welding, uses a non-consumable electrode, offering better process control than GMAW (MIG) but requires the addition of a separate filler material. In contrast, fiber laser welding is up to 10 times faster, delivering higher precision, lower heat input, and greater ease of automation, making it a more efficient and reliable option for a variety of applications.

“In my 41 years in the business, I have never seen a welder that allows beginners to make welds like seasoned pros!”

EUEN-WELD Factory Presets Ensure Optimized Welds & Cleaning

Simple preset selection guarantees consistent, high-quality laser welds and cleaning.

- Presets include a wobble welding function for wider seams and parts with poor fit-up.

Operators can quickly switch between presets to handle various material thicknesses.

Advanced users can customize and save presets for future use, allowing novice operators to achieve the same results with minimal training.

This reduces labor costs while maintaining quality, boosting productivity, and decreasing scrap.

EUEN WELD is Fast & Easy to Set Up

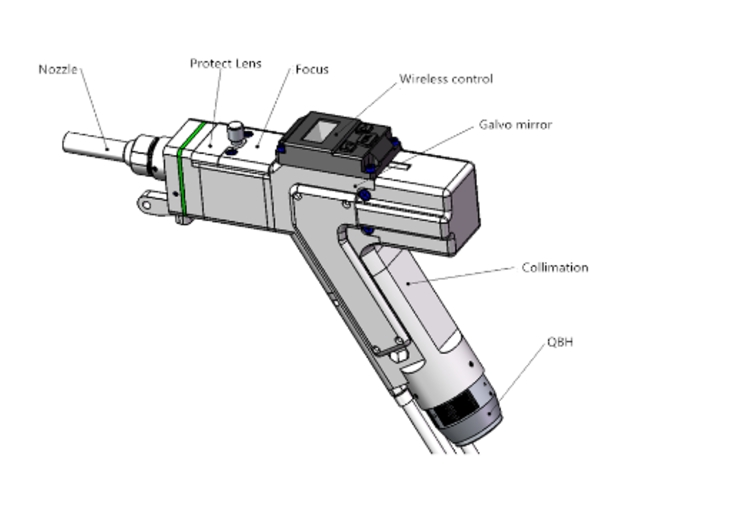

The ergonomic and compact laser gun is designed for comfort and ease of use, featuring built-in wobble welding functionality.

A 2-step trigger and part contact sensor enhance operator safety.

Purpose-built nozzle tips accommodate various weld joint types as well as pre- and post-weld cleaning applications.

Operators can quickly switch between standard laser welding, wire welding, and laser cleaning.

A single cable from the unit supplies laser power, gas, and control connections to the gun.

Fast and Easy Setup

Clearly labeled rear connections facilitate quick and easy setup.

Simply plug in the power cord and gas connection, attach the clamp to the work surface, and the system is ready to operate.

Laser power, gas, and gun control are all delivered through a single cable.

An Ethernet connection allows access to advanced parameter settings, enabling users to fine-tune and save process parameters.

EUEN WELD Operator Safety Features

The system features a key switch control to prevent unauthorized operation and an emergency-stop button for immediate shutdown.

A safety interlock verifies the integrity of laser delivery to the welding gun.

The 2-step weld gun trigger requires intentional operation to enable and then fire.

A part contact electrical interlock turns off the laser power if the welding head is not in contact with the workpieces.

Additionally, door switch interlock circuits shut down the laser if anyone other than the operator unexpectedly enters the welding area.

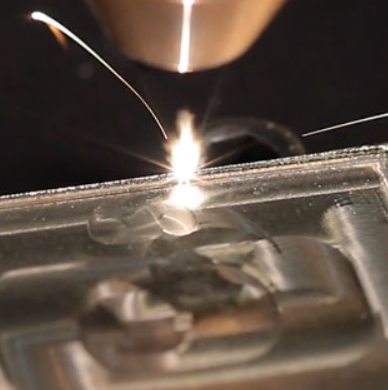

Optional Wire Feeding Package

The wire welding capability expands laser welding applications to accommodate poorly fitting parts. It is suitable for low carbon steel, stainless steel, aluminum, and various non-ferrous metals and alloys. The wire feed speed ranges from 40 to 600 cm/min (15 to 230 ipm), with a wire diameter capacity of 0.8 to 1.6 mm (0.035″ to 0.063″).

Wire feed tips available include 0.8 mm, 0.9 mm, 1.2 mm, and 1.6 mm. The system features 2x V-rollers and steel liners for hard wire, along with 2x U-rollers and Teflon liners for soft wire. The package includes the wire feed unit, electrical connections, nozzle assembly, and Process Mode software.

Advantages of Our Fiber Laser Welding

Highest Part Yield

The high stability of the laser power and beam profile of the EUEN fiber laser ensures a very repeatable process that delivers the same high-quality weld every time. This non-contact process with no wearing surfaces ensures the last part you produce is the same as the first.

High Throughput

The inherently high speed of laser processing combined with the ease of high-speed automation and elimination of most post-processing steps provide significantly shorter cycle times than competing technologies. Factor in the high-yield process, and EUEN fiber laser welding delivers more good parts faster than alternate joining techniques.

Fast ROI

Together with higher-speed and lower-cost processing, the high uptime and availability of the laser welding system enabled by the zero-maintenance EUEN fiber laser make for the lowest cost per part welding, and the fastest return on investment.