Laser Cleaning Machine

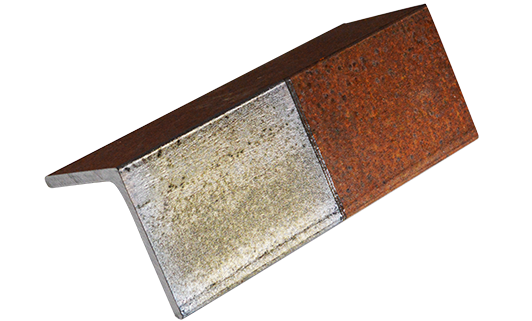

EUEN laser cleaning machine can provide high-speed cleaning and surface preparation in virtually all industries. The low-maintenance, easily automated process can be used to remove oil and grease, strip paint or coatings, or modify surface texture, for example adding roughness to increase adhesion.

No abrasive materials are used, with no problems of contaminant separation and disposal

No solvents are used – chemical-free and environmentally friendly process

Spatially selective – cleaning only the area required, saving time and costs by ignoring regions that don’t matter

Non-contact process never degrades in quality

Easily automated process that can lower operating costs by eliminating labor while giving greater consistency in results

Improve your cleaning productivity – contact us on WHATSAPP

Why are more manufacturers using laser cleaning for material preparation?

Laser cleaning offers multiple advantages over traditional approaches. It does not involve solvents and there is no abrasive material to be handled and disposed of. Compared with other processes that are less detailed, and frequently manual processes, laser cleaning is controllable and can be applied only to specific areas of a part, can be easily automated to maximize productivity, and provides the guaranteed repeatability demanded by an increasing number of quality standards.

Advantages of EUEN Fiber Laser Cleaning Technology

Elimination of Chemical Solvents

Handling and disposal of hazardous chemical solvents is eliminated by laser cleaning. The reduction in costs of consumable solvents and the expensive requirements for post process treatment and disposal of these chemicals are not a factor for laser cleaning, making it both the environmentally preferred and lowest cost solution.

Controllable Non-Damaging Process

Laser cleaning provides greater levels of control than are available for any competing process. The highly focusable and steerable laser beam can be directed precisely as desired, while sensitive and repeatable power settings deliver only the amount of energy that is called for. The range of EUEN fiber lasers includes pulsed models specifically designed to produce optimum cleaning results with a minimum of heat generation.

High Precision Flexibility

Laser cleaning is a uniquely flexible and precise process that is used in the surface preparation of metals, composites, and glass across a variety of applications and industries. No other ablation method is capable of highly-selective material removal with micron-level control across parts of all shapes and sizes.