Laser cutting machine

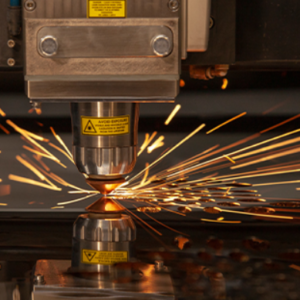

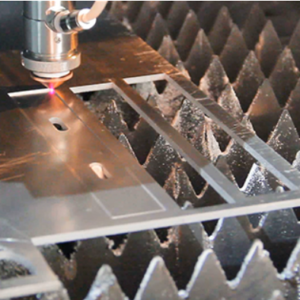

Laser cutting has become the go-to technology for advanced manufacturing due to its exceptional precision, speed, and quality. At EUEN, we leverage laser cutting as a dependable and cost-efficient solution, driving its extensive use in the metal manufacturing industry.

Advantages of fiber laser cutting include:

- Precise and consistent cutting results

- Rapid cutting speeds for increased efficiency

- Non-contact process ensuring superior cut quality

- Low maintenance requirements with high tool availability

- Versatility in cutting various non-metallic materials

- Scalable applications, from intricate micro-cutting to shaping large structural steel

- Easy automation for enhanced productivity

Enhance your cutting performance today- contact me on WHATSAPP

CO2 Laser Cutting vs. Fiber Laser Cutting

CO2 lasers are ideal for achieving smooth, clean edges on thicker materials exceeding 25 mm. Meanwhile, advancements in fiber laser technology have enabled them to deliver high-quality cuts on thicker materials as well. Fiber lasers also outperform CO2 lasers in cutting thinner materials, operating at higher speeds and excelling with reflective metals. This efficiency, combined with reduced operational costs, makes fiber lasers a cost-effective and versatile choice for various cutting applications.

Plasma Cutting vs. Fiber Laser Cutting

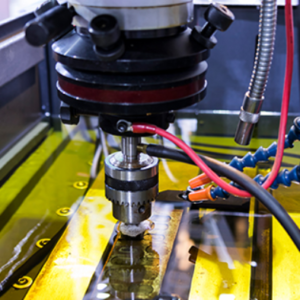

EDM Cutting vs. Fiber Laser Cutting

Electrical discharge machining (EDM) is renowned for its exceptional accuracy and minimal heat impact on materials. However, fiber lasers deliver comparable precision while operating up to 10 times faster than EDM. This remarkable speed advantage translates to significantly higher output and productivity, making fiber lasers a highly efficient choice for modern manufacturing.

Advantages of EUEN Fiber Laser Cutting Machine

Fast Cutting Speed

EUEN fiber lasers cut metal at speeds surpassing competing technologies. The 1 µm wavelength enables more efficient coupling than traditional lasers, and the excellent beam quality ensures greater energy density on the workpiece, resulting in faster cutting.

High Availability

Unlike other laser technologies, EUEN fiber lasers require zero maintenance, with no consumable gases or optics to align, eliminating preventative maintenance downtime. Built with rigorously tested long-lifetime laser diodes and an all-solid-state architecture, EUEN fiber lasers offer the best warranty in the industry.

Repeatable Process

Unlike competing lasers that may experience poor short-term stability and long-term power degradation, EUEN fiber lasers deliver consistent, repeatable performance. With power stability typically better than 0.5% of the setting over 1,000 hours of operation, you can expect the same cutting quality on every part.

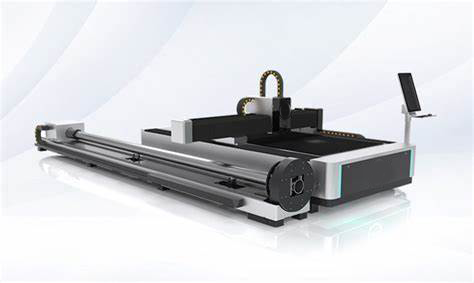

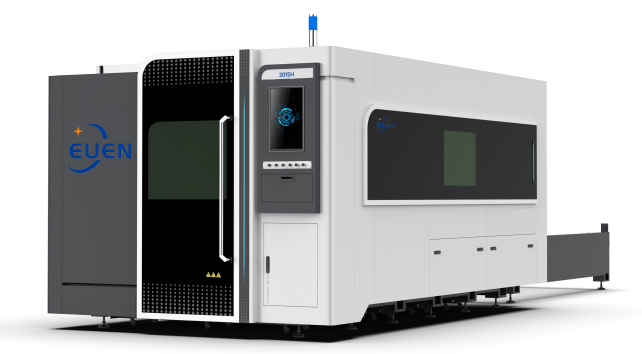

Full covered exchang table laser cutting plate machine

The fully enclosed laser protective cover, professional CNC cutting system, imported components, and strict assembly process ensure stable and high-precision operation of the cutting machine.

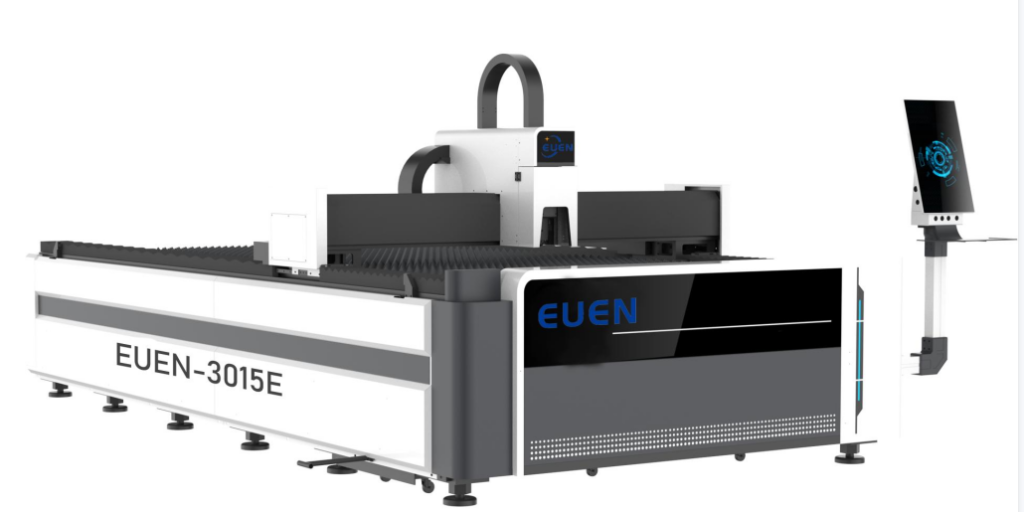

Open-single table Laser cutting plate machine

The metal sheet fiber laser cutting machine is simple to operate and easy to maintain, providing users with strong cutting ability and efficiency. Simple operating system for fast cutting of metal materials

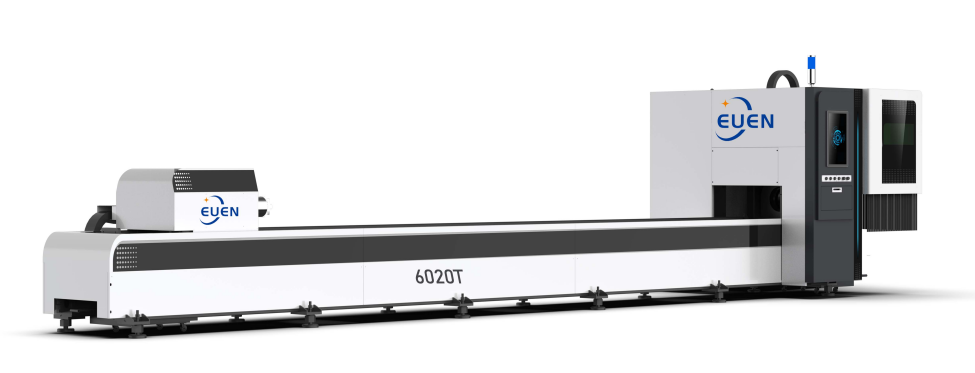

Laser cutting tube machine

The special optical fiber laser cutting machine for pipes solves the problems of low sawing efficiency and low accuracy of metal pipes. It can process round tubes, square tubes, and similar pipes. The size and power can be customized according to customer requirements.

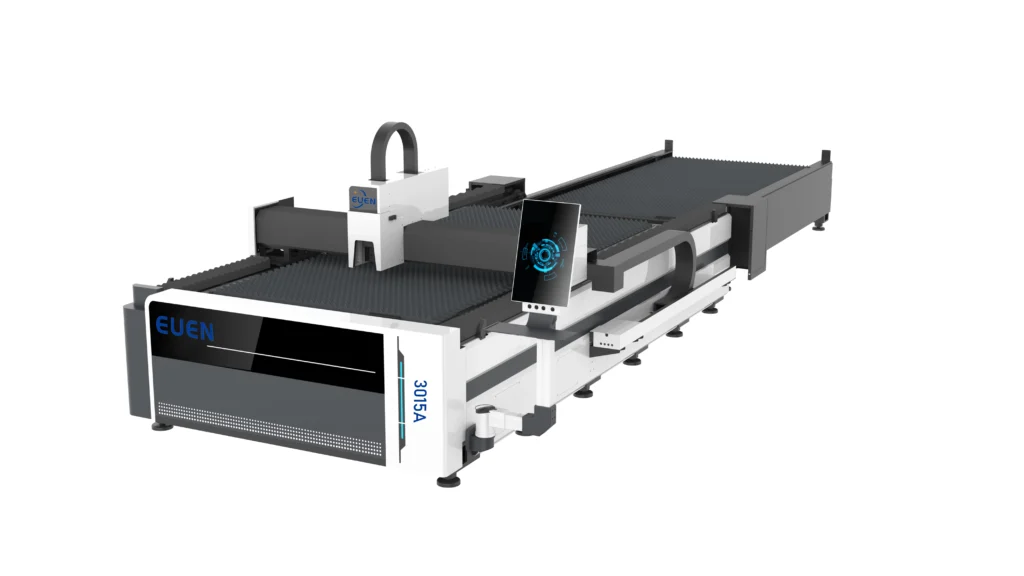

Exchang table Laser cutting plate machine

The Exchange Table Laser Cutting Plate Machine features a dual-table design for seamless material loading and cutting, maximizing efficiency and productivity. With advanced fiber laser technology, it delivers precise, high-speed cuts across various metal plates. Ideal for industries demanding accuracy, speed, and reliability.

Laser cutting plate/tube 2 in 1 machine

The plate tube integrated fiber laser cutting machine has a high performance cost, which can not only achieve the cutting of pipe metal sheets on a single machine, but also save more than 50% of the space and cost.